Related Products

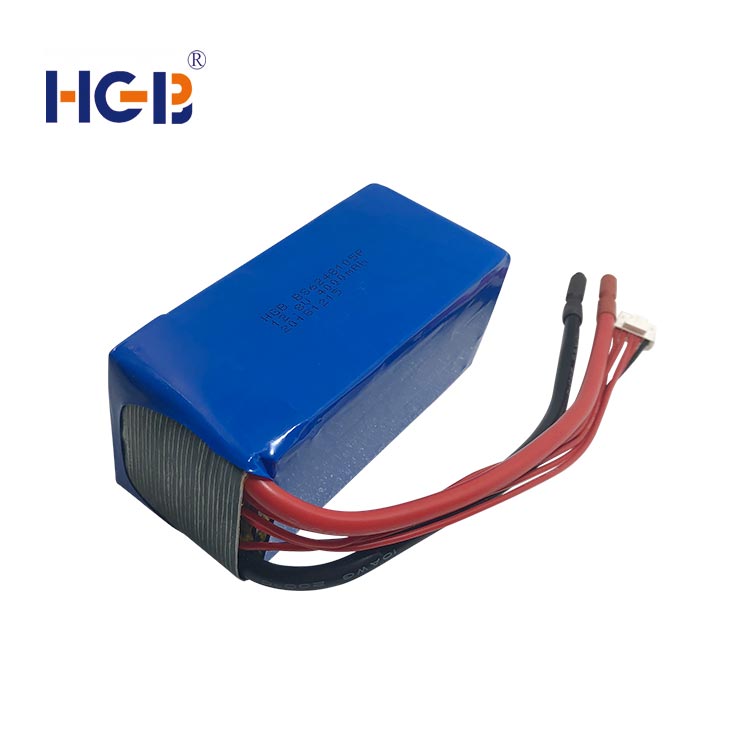

| Model | HGB6248105 |

|---|---|

| Dimension | 50*49*115mm (thickness*width*length) |

| Nominal Voltage | 12.8V |

| Nominal Capacity | 4000mAh |

| Discharge current | 40C@80A |

| Charge current | 1C@2A |

| Cut-off voltage | 10.4V |

| Full voltage | 14.6V |

| Cycle life | 2000 times |

| Operating Temperature | -30 ~ +60℃ |

| Color | blue |

| Material | LiFepo4 |

| Connector | UL1571 AWG10, 5Pin-connector |

| Label | HGB OR OEM |

| Assembly Way | 4S2P,battery cell |

| Application | Vehicle start/stop |

| Brand | HGB |

| Rechargeable | Yes |

| Payment term | T.T / L.C / PAYPAL / WESTERN UNION |

| MOQ | 10 pack |

| Lead time | 20-25 days |

| OEM service | Welcome ( SPECIAL PRICE FOR BIG ORDER) |

| Warranty | 12 Months |

Copyright © 2025 HGB Battery Co.,Ltd. | All Rights Reserved